Biomedical quality standards are particularly high: integrity and conformity of the product, maximum reduction and elimination of defects are essential conditions for consumer health so as for the producer's reputation. Our vision systems guarantee a precise, high speed and fully tracked control of all production, assembly and packaging processes of biomedical products.

Imago collaborates with the most important italian companies in the sector; our systems are installed on hundred of machines and production lines.

Integrity check of the various components based on precise geometric criteria.

The type of the loaded product is controlled to avoid product/package mismatch

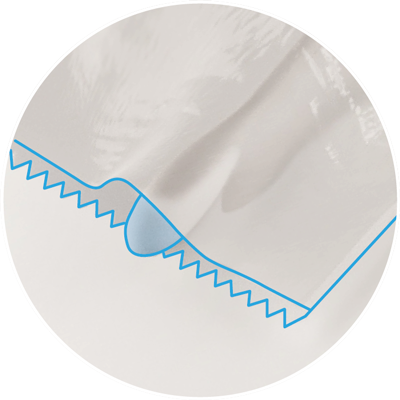

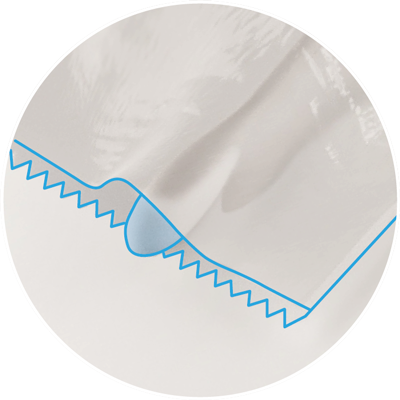

Checking the presence of any foreign bodies between the upper and lower film that can affect the sealing quality

Checking the product loading position to prevent any damage to the sealing gaskets, thus saving unnecessary maintenance costs and machine downtime

Checking the correct position and/or integrity of the cut or blanking

Check of the upper film and its positioning

Analysis and verification of all printed data such as lot number, expiration date, identification codes and the like

Reading, verification and qualitative analysis of all printed codes according to the latest ISO standards for correct code/product matching

Integrity check of the various components based on precise geometric criteria.

The type of the loaded product is controlled to avoid product/package mismatch

Checking the presence of any foreign bodies between the upper and lower film that can affect the sealing quality

Checking the product loading position to prevent any damage to the sealing gaskets, thus saving unnecessary maintenance costs and machine downtime

Checking the correct position and/or integrity of the cut or blanking

Check of the upper film and its positioning

Analysis and verification of all printed data such as lot number, expiration date, identification codes and the like

Reading, verification and qualitative analysis of all printed codes according to the latest ISO standards for correct code/product matching

Reading and marking of DataMatrix, QR code, Barcode and various types of stamps.

Objectified and tracked checks for each individual piece. Data storage and display for statistical analysis of production and process optimization.