After the trimming phase, it is very important to check the integrity of the part. Anglerfish performs this type of control in 3D and inspects the flatness and regularity of the trimmed areas, detecting excesses or defects of material up to 0.3 mm and eventual, even partial, occlusions of the holes.

Several defects that normally become visible only after machining can be prevented, thus avoiding waste.

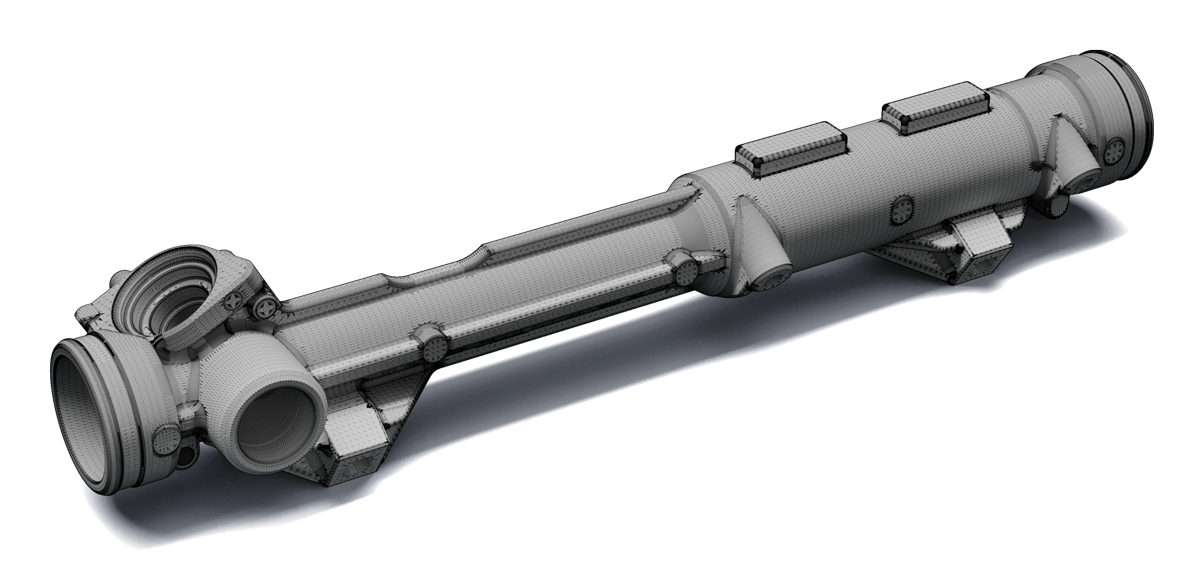

Anglerfish for Steering Housing is a particular Anglerfish vision system that allows you to identify and check the defects of the Steering Housing. This inspection takes place after the trimming phase through a 3D control system that can examine parts of any shape and complexity.

Anglerfish for Steering Housing inspects a part in a few seconds and is able to identify defects of various kinds in a few steps, by comparing it with a a dynamic and constantly updated reference.

Flexibility, precision and ease of use give Anglerfish for Steering Housing enormous potential, which guarantees an undisputed competitive advantage to the company.

To find out more, visit the dedicated page

Modern die casting products require specific, objectified and documented quality controls. This kind of technology can’t anymore rely on the naked eye for defects detection. In addition to effective inspection, complete control at all stages of the production cycle allows you to track all production and interact with machines in real-time, resulting in an overall improvement in quality.