We have been designing artificial vision systems for quality control and production tracking for over 20 years. Every day we put our know-how at the disposal of companies, helping them create added value for their business.

MISSION: "We help our customers to create added value by solving their needs."

The installation of our vision systems offers to our customer companies the opportunity to increase the technological level of their machine or production line, according to all the standards required by Industry 4.0, for a significant competitive advantage.

Our main partners are the manufacturers of machines, plants, production lines and automation.

Each project is unique: it starts with a feasibility analysis. The system design is then devised with great attention to the technical and economic targets. We are keen to keep in touch with our customer and we believe that joint planning helps us to achieve best results.

We develop turnkey systems, line-side applications and custom prototype projects. All our solutions are easily integrated and able to communicate through various protocols with other devices; they operate without contact and at very high speed.

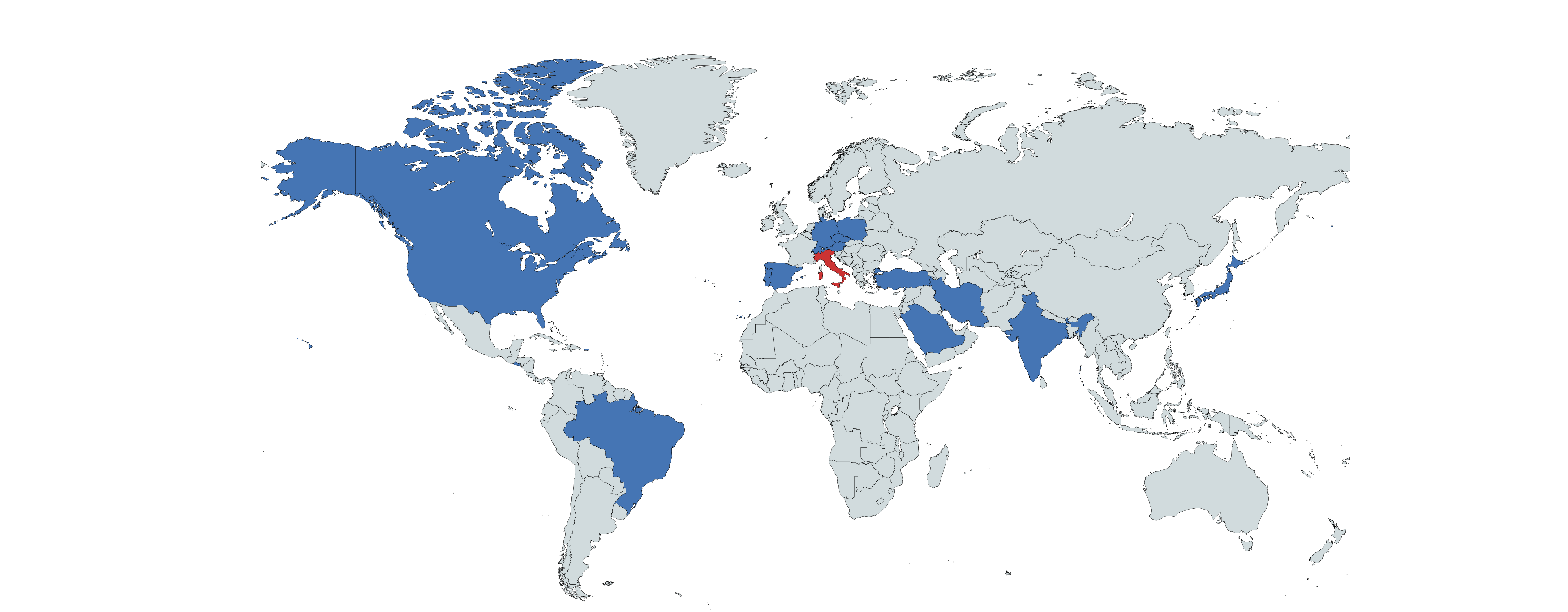

Our control and vision systems are installed in different countries and easily reachable in real time, through a specific remote assistance software.

In its twenty years of experience in technological precision, Imago has established and consolidated partnerships with the most important companies of metallurgy, die casting, thermoforming and biomedical sectors. With our systems we offer the possibility to radically enhance their performance, to monitor with absolute precision the entire production cycle and exponentially increase the quality of their products, always starting from the unique and specific needs of each individual company.